Who doesn't want a 5 axis CNC milling machine that fits on your desktop.

Kickstarter launch: Mid 2015

First delivery goal: Late 2015

Target Price: $3500USD

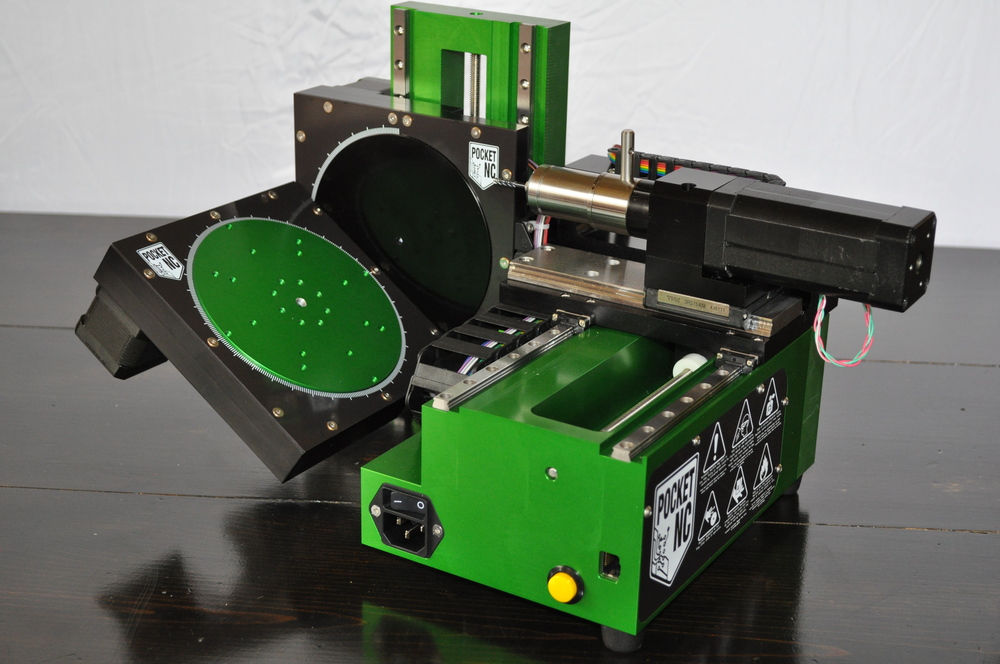

Our entry into market product is the Pocket NC. The Pocket NC is a 5 axis desktop CNC mill.

CNC milling machines have been around for decades. Most are industrial-sized, and are used create everything from the shaped trim in a house to the mechanical components of the space shuttle. To operate, a piece of material(metal, plastic, etc) is fastened to a bed and a cutting tool is used to shape it to the desired product. With computer control, the cutting tool and the part itself are maneuvered to achieve the desired cuts. In it's most simple form, a CNC milling machine can remove material in 3 translational axes of motion (X, Y, an Z). To enable the manufacturing of more complex parts, additional rotational axes of motion can be incorporated. For this machine, the part being cut would be fixed to the green disk.

Over the last decade, a large do-it-yourself community has emerged giving a new market to CNC milling machines as personal rather than solely industrial applications. Many machines exist in the 3 axis market with varying degrees of complexity and accuracy. However, the 5 axis market has yet to be crossed to the hobby realm, and that is where Pocket NC P5 fits in.

Pocket NC intends to produce and sell 5 axis machines that will allow at-home users to expand the possibilities of their creativity without being prohibitively expensive.

The level of precision of the machine will also be such that it could enable a user to create parts as an personal business, or serve as an accessory to larger manufacturing facilities thus freeing up the large industrial machines from making relatively tiny parts.

Max Speed: 40 ipm (inches per minute)

Resolution: 0.000125in

Backlash at 100% load : 0.003in

Max Travel: 4.5 in

Homing Repeatability: - +/-0.0005 in

Repeatability: +/-0.002 in at 0% load

Y Axis

Max Speed: 40 ipm (inches per minute)

Resolution: 0.000125 in

Backlash at 100% load : 0.003 in

Max Travel: 4.8 in

Homing Repeatability: - +/-0.0005 in

Repeatability: +/-0.002 in at 0% load

Z Axis

Max Speed: 40 ipm (inches per minute)

Resolution: 0.000125in

Backlash at 100% load : 0.003in

Max Travel: 3.45 in

Homing Repeatability: - +/-0.0005 in

Repeatability: +/-0.002 in at 0% load

A Axis

Max Speed: 20 degrees/second

Resolution: 0.025 degrees

Backlash at 100% load : 0.05 degrees

Max Travel: 100 degrees (90 degrees +/- 5 degrees)

Homing Repeatability: - +/-0.05 degrees

Repeatability: +/-0.05 degrees at 0% load

B Axis

Max Speed: 40 degrees/second

Resolution: 0.025 degrees

Backlash at 100% load : 0.05 degrees

Max Travel: continuous rotation

Homing Repeatability: - +/-0.05 degrees

Repeatability: +/-0.05 degrees at 0% load

Spindle

Spindle Speed: 65-10,000 rpm

Power Output: 104 Watts

Spindle Motor: BLDC 3 Phase with Hall Feedback

Spindle Runout: 0.000078in

Tool Change: Lever Type (no wrenches needed)

Tooling: 1/8in or 3mm shank

Machine Control

BeagleBone Black running Machinekit/

Features

Spindle Override

Feed Override

Stop, Start, Pause

Jog while pause

5 axis simultaneous movement

Ethernet connection

Accepts Standard Gcode

Power Source: 90-264 VAC, 127-370 VDC, 47-63H

Components

7 NEMA 17 Motors

3 linear lead screws with preloaded nuts

4 rotary 8/1 belt drives

Linear Bearings, 9 & 42mm, 10% preload

Angular contact rotary bearings

6061 Aluminum Frame, +/-0.002in squareness

Machine Dimensions:

Fully extended: 17.5 in wide(444.5 mm) x 12.5 in (317.5 mm) tall x 11 in (279.4 mm) deep

Fully compressed: 13 in wide (330.2 mm) x 9.5 in (214.3 mm) tall x 9 in (228.6 mm) deep

Software

Autodesk Fusion360, post processor included